Strainer for gas

| 1. Working pressure (MPa): | 1.0, 1.6, 2.5, 4.0, 6.3 |

| 2. Execution standards: | Q/JD2.005-2010 |

| 3. Medium viscosity (mPa. s): | Media with volatility ranging from 0.8-20 are not suitable for use with degassing filters. |

| 4. Installation and usage requirements: | Please follow the instructions for installation, use, and maintenance. |

| 5. Flange standards: | JB/T79-82-1994, GB/T9112-2000 (can also be manufactured according to relevant standards according to user needs) |

| 6. Material requirements: | Generally, it is composed of a filter and a damper. |

| A. Filters: | cast iron, stainless steel, carbon steel |

| B. Exhaust valve: | shell - carbon steel, valve core - stainless steel |

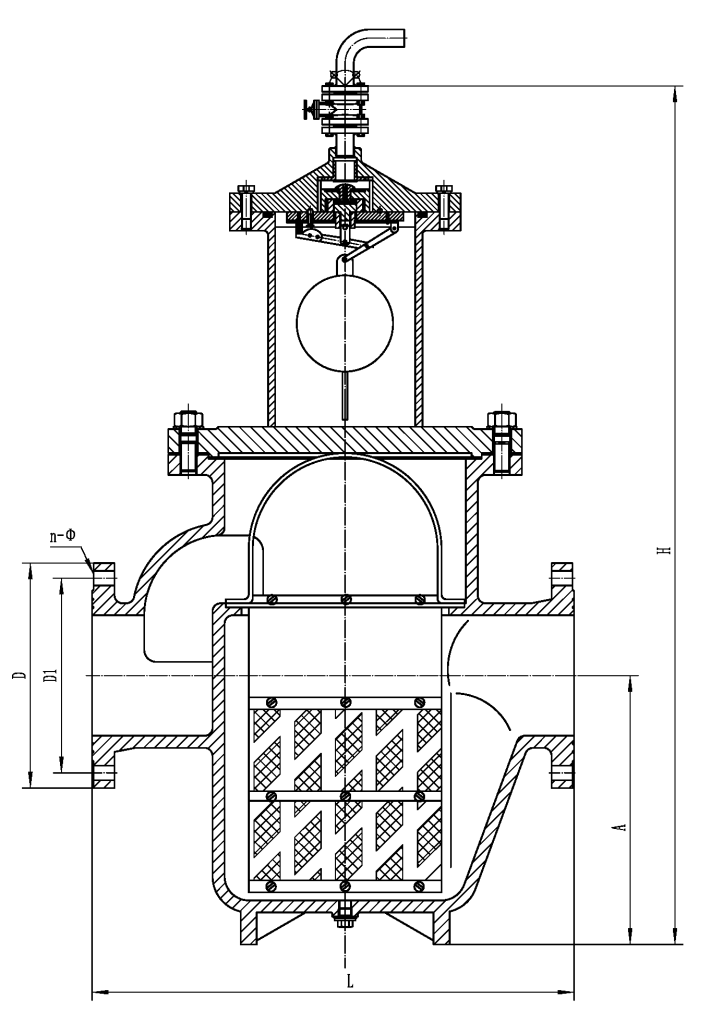

1.The LPG-X series degassing strainer as an auxiliary equipment for flow measurement, the main function is to Strainer the particulate impurities contained in the measured liquid, and can separate and exclude a small amount of gas in the measured liquid (general gas content is less than 5%).

2.In most cases, the measured liquid will contain various impurities and gases to varying degrees. These impurities and gases enter the flowmeter and will affect the metering accuracy of the flowmeter. Therefore, in the flow metering system, especially in the high-precision flow metering system, the Degassing Strainer is an indispensable auxiliary equipment.

Structure:

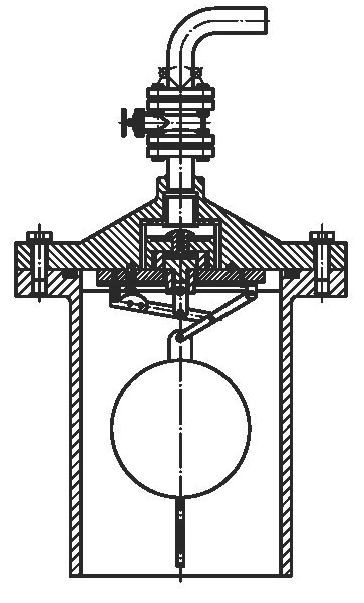

The Degassing Strainer consists of a shell, a degassing valve, a Strainer screen and other main parts. The shell shall withstand the working pressure of the liquid to be measured, and form a space to meet the requirements of filtration and deaeration. The air damper moves up and down through the float ball to control the switch of the main valve and the auxiliary valve to achieve the purpose of exhaust.

Working principle:

The special specifications put forward by users can also be designed and manufactured.

- Strainer

Tags: