High quality high precision Metal Scraper Flowmeter

| Accuracy class: | class 0.5, class 0.2 |

| Environmental temperature(℃): | -41~60(Cast iron material:-15~60) |

| Working Temperature(℃): | -20~60 |

| Sender type: | Type BGF pulse volume transmitter、BMF analog signal transmitter. |

| Output : | BGF-I pulse amplitude 0.5~9V;BGF-II pulse amplitude 1~20V;BMF analog signal(4~20mA) |

| Supply Voltage: | BGF-I DC12V、BGF-II DC24;BMF DC24V. |

| Explosion proof sign: | ExdIICT6,ExiaIICT6 |

| protection grade: | IP66 |

The LBJ Series Metal Scraper Flowmeter is a positive displacement flowmeter. Used for continuous or intermittent precision measurement of liquid flow through pipelines.

The LBJ Series Metal Scraper Flowmeter adopts double shell structure, the rotor rotates at the same speed, with smooth operation, no pulsation, low noise, large flow, sand control, high measurement accuracy, long service life and viscosity change adaptability, widely used in petroleum, chemical, light industry, transportation, commercial and other departments, especially suitable for measuring crude oil, residual oil, refined oil, light hydrocarbons and other media transfer and trade settlement measurement. Flowmeter can be indicated on the spot and can be remote signal output.

Working Principle:

When the measured liquid enters the flow time,the liquid impacts the scraper, pushes the scraper and the rotor to rotate clockwise along the cam, and the scraper expands and expands along a certain track with the cam, and forms an accurate measuring chamber with the rotor, the inner shell, the cover plate, etc., with the continuous rotation of the rotor and the scraper, the purpose of measuring the measured medium is achieved.

Main technical parameters:

Nominal diameter (mm):25,40,50,80,100,150,200,250,300

Nominal Pressure(MPa):1.6,2.5,4.0,6.3

Working Temperature (℃):-20~60,

Environmental temperature(℃):-41~60(Cast iron material:-15~60)

Accuracy grade :0.5,0.2

Sender type:Type BGF pulse volume transmitter、BMF analog signal transmitter.

Output :BGF-I pulse amplitude 0.5~9V;BGF-II pulse amplitude 1~20V;BMF analog signal(4~20mA).

Supply Voltage:BGF-I DC12V、BGF-II DC24;BMF DC24V.

Flange standard:GB/T9112-2010,or according to user requirements.

Explosion-proof sign:ExdIICT6,ExiaIICT6

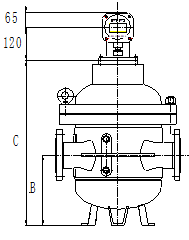

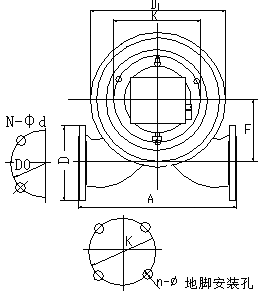

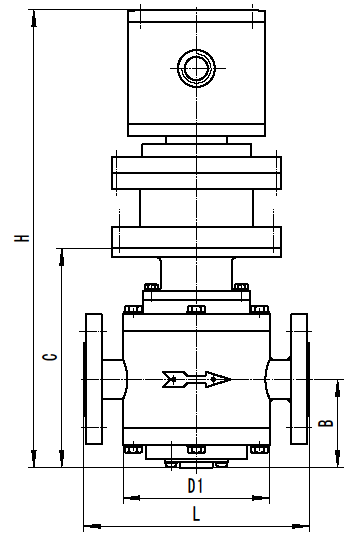

Flowmeter appearance and connection:

Machinery installation:

1.The installation position of the flowmeter should try to avoid the environment with large mechanical vibration, high temperature and strong magnetic field interference. And choose the location for easy maintenance installation.

2.Install the flowmeter on the new pipeline, in order to avoid impurities in the pipeline into the flowmeter, you can first replace the flowmeter with a section of pipe, clean the pipe, and then replace the flowmeter.

3.The flowmeter should be installed on the main channel of the horizontal pipeline, and the bypass pipeline should be set up according to the figure below for easy cleaning and maintenance.

4.The arrow direction on the installation flowmeter body should be consistent with the direction of liquid flow. Counter oriented can be adjusted according to user needs.

5.The strainer is installed before the flowmeter is imported. In order to make the measurement accurate, the gas in the pipeline should be excluded, and the gas eliminator should be installed.

6.Flowmeter regulating flow valve should be installed on the downstream side of the flowmeter.

7.Both ends (flanges) of the flowmeter should be concentric with the pipe, and when connected with the flowmeter, the sealing gasket can not burst into the liquid.

Welcome to ask us for detailed product manuals.

- Metal scraper flowmeter

Tags:

-

Prev : High precision and digitalization Dual Rotor Flowmeter

-

Next : High quality high precision Graphite Scraper Flowmeter