LPG Liquefied petroleum gas dispenser

The machine is equipped with high-precision volumetric flow meters, microcomputer control, large LCD display counters, and various control valves and protective devices to ensure safe operation.

The gas dispenser adopts advanced manufacturing technology, with reliable quality and excellent operational performance.

It has the characteristics of accurate quantitative gas filling, convenient maintenance and repair, centralized control, and can adapt to the needs of future national fee to tax reform. Each gun in the gas dispenser has an independent liquid flow and metering system, which does not affect each other during refueling.

Product labeling:

JQ060L-A-1G Cantilever Single Gun Gas Dispenser

JQ060L-B-2G Longmen Double Gun Gas Dispenser

JQ060L-C-1G Small Cabinet Filling Machine

JQ060L-D-4G Longmen Four Gun Gas Dispenser

JQ060L-E-6G Longmen Six Gun Gas Dispenser

Main technical parameters:

- Single gun flow rate: 10L/min~60L/min

- Maximum working pressure: 2.5Mpa;

- Working environment temperature:- 30℃~+55℃;

- Measurement accuracy: 1.0%;

- Power supply: AC220 ± 15%, 50 ± 1Hz

- Explosion proof grade: Exmdib II AT4

Major function:

1.Automatic control of gas filling process, with dual sided automatic display of gas filling volume, filling amount, and unit price (display with night light).

2.Gas dispenser refueling pricing display: “refueling volume”, “unit price of one yuan/L”, “amount of one yuan”, and equipped with a pressure gauge to display pressure.

3.Equipped with power-off data protection, displaying the current refueling data.

4.Large capacity storage, capable of querying refueling data no less than 12000 times.

5.Monitoring system: Monitor the temperature and flow rate during the inflation process, control the inflation speed, and automatically close the valve for protection when the pressure and flow exceed the standard.

6.Built in imported clock system, accurate and reliable timing even after power failure.

7.You can check the total accumulated amount at any time.

8.Equipped with preset gas filling function with fixed gas volume and fixed amount.

9.Adjustable flow rate and density.

10.Configure inlet ball valve.

11.Can check each refueling data and refueling time;Can query the cumulative gas volume, amount, total cumulative gas volume, and total cumulative amount of refueling during the shift.

12.Equipped with automatic fault detection function, capable of displaying fault codes automatically.

13.During the inflation process, the flow rate and temperature can be directly displayed to ensure safe refueling.

14.Equipped with a manual emergency shut-off valve.

15.No traffic signal, automatic shutdown to protect the interests of homeowners.

16.Equipped with RS485 communication, it can communicate with the computer management system of the gas station.

17.Capable of printing receipts;

18.Equipped with all the functions of an IC card gas dispenser, the dispenser has obtained national explosion-proof certification.

19.When the IC card machine is linked to the gas dispenser, advanced algorithms are used to generate and manage the IC card key.Ensure the data security of IC card users.

20.Small traffic protection.

21.Optional metal keyboard.

22.All parameters are accessed through password, and the relevant device information can only be modified after entering the correct password.

23.Thermal insulation devices can be installed on electronic devices in high-altitude areas.

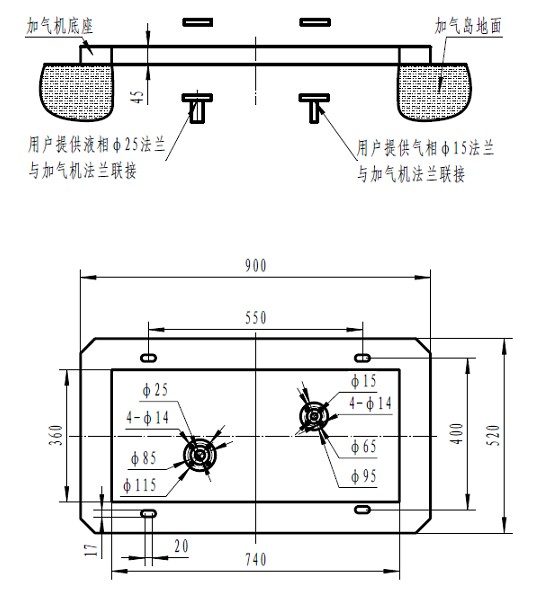

Installation foundation diagram:

Other:

Overall dimensions: length x width x height=900 x 520 x 1850 (2080) mm

Weight: Approximately 300Kg

- Gas dispenser

Tags:

-

Prev : CNG Compressed natural gas unloading column

-

Next : LNG Liquefied natural gas refueling machine