Intelligent and digital gas Roots flowmeter

| Accuracy class: | class 0.5, class 0.2 |

| Ambient temperature: | -20℃~55℃ |

| Medium temperature: | -20℃~+60℃ |

| Signal output: | 4-20mA analog signal, pulse signal, RS485, HART, etc. are available for selection. |

| Explosion proof sign: | ExiaII CT4Ga |

| protection grade: | IP65 |

The LLQ series Roots Flowmeter suitable for non corrosive gases such as natural gas, city gas, propane, butane, air, nitrogen, and industrial inert gases.

It is mainly used for gas commercial settlement in industries such as catering and hotels, gas metering in transmission and distribution pipelines, gas pressure regulating stations, industrial and civilian boilers, and can also be used as a standard flow meter.

This product complies with JB/T7385-2015<Gas Roots Flowmeter>and JJG633-2005<Gas volumetric flowmeter calibration regulations.

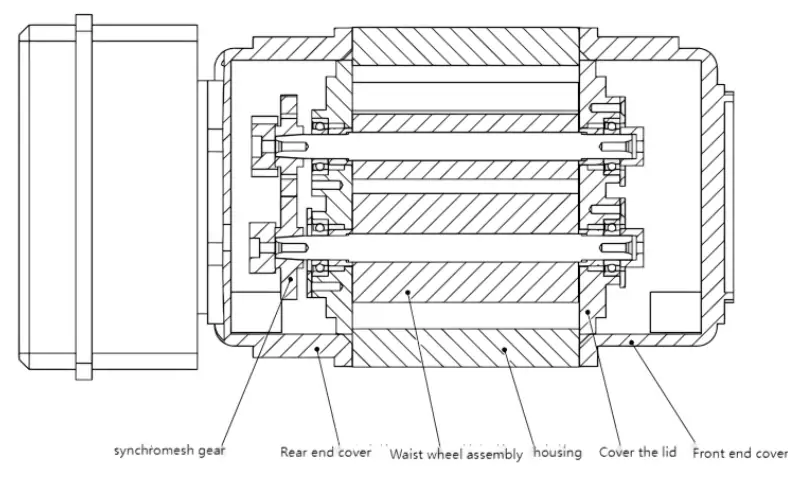

Flowmeter structure:

Working principle:

This flowmeter is a positive displacement flowmeter, and the measuring chamber consists of two rotors with a waist wheel shape in cross-section that mesh and rotate. As gas flows through the measuring chamber, the pressure difference force generated between the inlet and outlet of the measuring chamber drives the two waist wheel rotors connected to a pair of high-precision synchronous gears to rotate, completing the rotation process from A-B-C-D. The gas in the measuring chamber formed by the enclosed space between the inner wall and cover plate of the measuring chamber and the pair of waist wheel rotors periodically enters and exits the chamber; The rotational speed of the waist wheel rotor is proportional to the flow rate of the measured gas passing through the flowmeter. The rotational speed value is transmitted through a dedicated sensor to the integrator for shaping and filtering, and then converted into a standard voltage pulse signal output. The frequency of the pulse signal is proportional to the common volume flow rate of the fluid inside the pipeline.

The built-in high-precision pressure and temperature sensors simultaneously measure the temperature and pressure of the fluid and transmit signals into an integrated intelligent integrator. The integrator converts the signals of flow rate, temperature, and pressure and accurately calculates and integrates them to accurately measure the standard volume flow rate and mass flow rate of the gas.

Main technical parameters:

Flow meter specifications, basic parameters, and performance indicators (see Table 1)

Table 1

| Specification and model | Nominal diameter (mm) | Flow range m3/h | Start flow rate m3/h | Pressure loss at Qmax | Accuracy% | Nominal pressure MPa |

| LLQZ-25 | 25 | 1-25 | 0.05 | 0.08 | 1.01.5 | 1.6 |

| LLQZ-40 | 40 | 1-40 | 0.07 | 0.08 | 1.6 | |

| LLQZ-50A | 50 | 2-65 | 0.1 | 0.1 | 1.6 | |

| LLQZ-50B | 50 | 2-100 | 0.1 | 0.15 | 1.6 | |

| LLQZ-80A | 80 | 3-160 | 0.12 | 0.15 | 1.6 | |

| LLQZ-80B | 80 | 3-250 | 0.15 | 0.18 | 1.6 | |

| LLQZ-100A | 100 | 4-300 | 0.11 | 0.35 | 1..6 | |

| LLQZ-100B | 100 | 4-500 | 0.1 | 0.46 | 1.6 | |

| LLQZ-150A | 150 | 8-650 | 0.65 | 0.47 | 1.6 | |

| LLQZ-150B | 150 | 15-1000 | 0.76 | 0.49 | 1.6 |

Welcome to ask us for detailed product manuals.

- Roots Flowmeter

Tags:

-

Prev : Intelligent and digital gas Turbine flowmeter

-

Next : Integrated intelligent temperature and pressure compensation Vortex Flowmeter