Intelligent explosion-proof constant value controller

The EL-5092B series explosion-proof constant value controller (also known as loading controller, batch filling controller) is widely used in automatic quantitative loading and barrel loading of petroleum and chemical products, batch filling control, high-precision mixing ratio distribution and control of multiple media, and intermediate metering function in the production process.

It is the basic unit of the automated distribution system.

The EL-5092BK explosion-proof constant value controller is a forward-looking product in this series of products. It adopts a high-speed and ultra large scale enhanced industrial grade SOC core, non-contact IC card technology, and the latest electronic technology. It has the advantages of high measurement accuracy, fast operation speed, strong anti-interference ability, long communication distance and high-speed reliability, easy operation, and easy maintenance.

The operating chassis adopts an explosion-proof design and contains a non-contact IC card reader inside, which can divide different non-contact IC cards into administrator and operator level 2 permissions, perform level 2 password management, and display a large screen backlit graphic LCD screen with 320×240 dot matrix, displaying up to 15 lines of Chinese characters, with a large amount of information displayed, convenient for customer operation, and a friendly interface.

To improve the transparency of the EL-5092B series explosion-proof constant value controller, all parameters inside the machine are open to the user, meaning that the operator can know any parameter inside the machine through the keyboard. The EL-5092B explosion-proof constant value controller has a single channel quantitative control function. EL-9052BK has multiple control modes such as single channel quantitative control and dual channel quantitative control.

This series of products not only has advanced technology, but also has forward-looking superior performance. The operating interface is intuitive and clear, making it the preferred product for the storage and transportation department in the petrochemical industry.

Function and Features:

- It has two working modes: remote networking and local standalone.

- The chassis adopts explosion-proof design and can be installed separately or in a dedicated operation cabinet.

- There are two shipping methods: barrel shipping and ship to ship shipping.

- It can be shipped directly by quality or volume and uploaded to the upper computer at the same time.

- It has two methods: manual temperature setting and automatic temperature collection, and has automatic temperature compensation function.

- It has the functions of power failure protection and memory of the working status before power failure. It can continue to work after receiving a call, and on-site work has oil delivery start button and emergency stop button.

- It can be equipped with an external high brightness large character display, which displays synchronously with the controller.

- Equipped with RS-485/232 communication interface, it forms a monitoring and oil delivery management system with the upper computer.

- Three level lightning protection and anti-static circuits have been added to the communication line, with strong lightning and anti-static capabilities.

- Important parameter operation permission setting function (metrology engineer operation password)

- Equipped with flow and valve indicator lights for easy fault diagnosis.12. Non contact IC card design, users can achieve IC card hierarchical permission control and identity recognition management according to their requirements.

- Backlit monochrome Chinese character LCD display (320×240 dot matrix, 20 characters x 15 lines of Chinese characters), with beautiful and elegant display, not affected by ambient light, clear and beautiful.

- Customizable color LCD display module (320×240 dot matrix, 20 characters x 15 lines of Chinese characters).

- The operating temperature ranges from -30 ℃ to 80 ℃, and customization is required.

- It has dual channel simultaneous control of filling and dispensing functions.

- Able to accept signals from static grounding switches (no oil can be dispensed without connecting static clamps)

- Able to accept oil spill level switch signals (automatically stop the pump and close the valve in case of oil spill)

- It has remote computer control, local single machine control, ticket control, IC card control and other material issuing methods.

- Store 100 offline records per crane position in the machine.

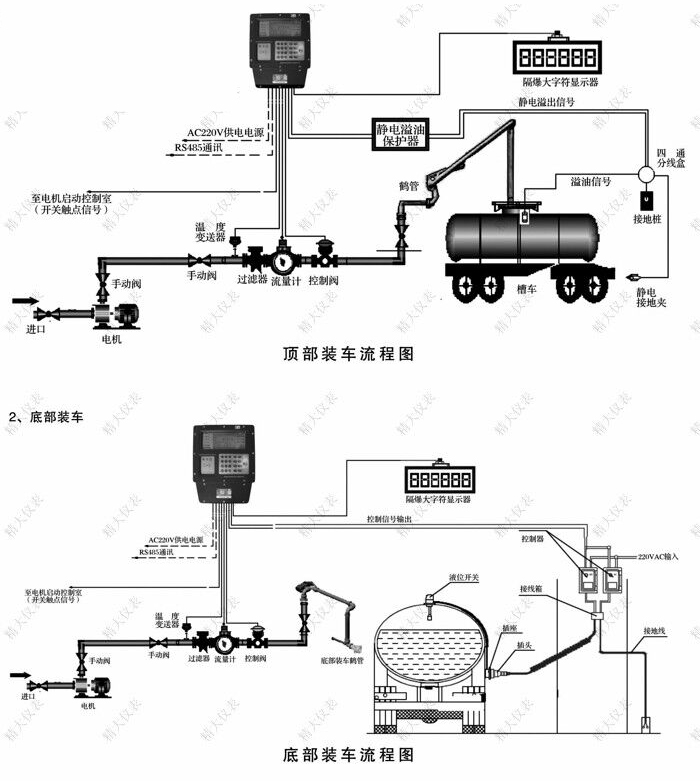

The typical process composition of the system is shown in the following figure:

Welcome to ask us for detailed product manuals.