Intelligent Explosion proof Batch Controller

The EL-2008 explosion-proof batch controller is a new type of intelligent explosion-proof quantitative control instrument, which uses high-performance microprocessors and is a true single-chip system.

The EL-2008 explosion-proof batch controller adopts a backlit LCD display, which is not affected by light, has a simple structure, high reliability, and can be directly installed in explosion-proof operation sites, oil tankers, and other occasions that require on-site explosion-proof quantitative measurement. Paired with various pulse output flow meters, it can quantitatively fill, measure, and control the flow rate in terms of mass or volume.

This instrument can be controlled by inserting parameters through the panel and has power-off protection function, making it an ideal unit instrument for modern control.

Main technical parameters:

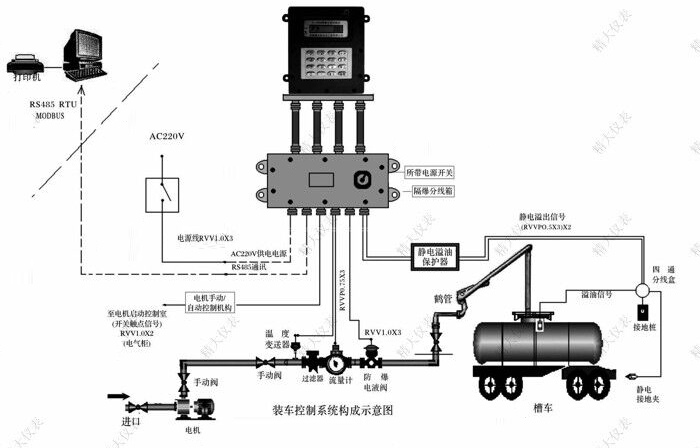

- Flow signal input: Two wire or three wire (pulse) frequency signal.

- Temperature signal input: 4-20mA current signal input, with adjustable upper and lower temperature limits.

- Grounding signal input: dry contact input, disconnect alarm.

- Overflow signal input: dry contact input, closed alarm.

- Output signal

A. One stage valve control output: 24V, 0.1A (equipped with DC24V universal relay)

B. Two stage valve control output: 24V, 0.1A (equipped with DC24V universal relay)

C. Pump control output: 24V, 0.1A (with DC24V universal relay)

D. Shift data signal output: Can be paired with a high brightness on-site large screen data display, synchronously displaying actual output standard 485 communication, communication protocol is RS-485 MODBUS RTU.

Maximum cumulative quantity: 999999 (liters, kilograms, or tons)

Fixed value range: 1-999999, advance quantity range: 1-99

Pulse equivalent setting range: 0.0001-99.9999L/P

Density setting range: 0.0001-99.9999 kg/L

Accumulated error: ± 1 pulse

Interval time: 1-99s Batch: 1-99 times

Environmental temperature for use:- 20℃~50℃

Power supply: AC220V or DC24V; Whole machine power: 30W

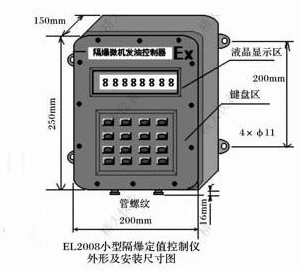

Overall dimensions of the machine: 250 (height) X200 (width) X150 (wall mounted)

Electrical interface: G4/3"X4

There are three batch control and quantitative control methods for this machine:

- Local mode: Local operation mode, all operations are completed on the batch controller, which has full permissions. Data can be uploaded to DCS or other upper level systems for collection and display.

- Remote mode: All operations are completed on the upper computer. Parameter setting and modification are both operated on the upper computer, enabling remote control with full permissions. The batch controller only has the permission to view parameters and emergency pause.

- Ticket number control mode: The upper computer issues a ticket, the batch controller inputs the ticket number, retrieves the corresponding material issuance parameters of the upper computer, and the batch controller implements the material issuance operation. But the batch controller does not have the permission to modify parameters.

System composition and wiring diagram:

Welcome to ask us for detailed product manuals.